Fabrication, Installation, and Startup of NRUs

The success of a Nitrogen Rejection Unit (NRU) depends not only on its design but also on its fabrication, installation, and startup. Poor execution in these phases can lead to operational issues and costly downtime. This blog explores best practices for NRU fabrication and startup, addressing common pitfalls and solutions.

Fabrication Concepts

- Cold Box vs. Modular Skids:

- Cold Box: Traditional NRUs use a perlite-insulated “cold box” for low-capacity installations, minimizing heat loss. However, restricted access complicates troubleshooting and repairs.

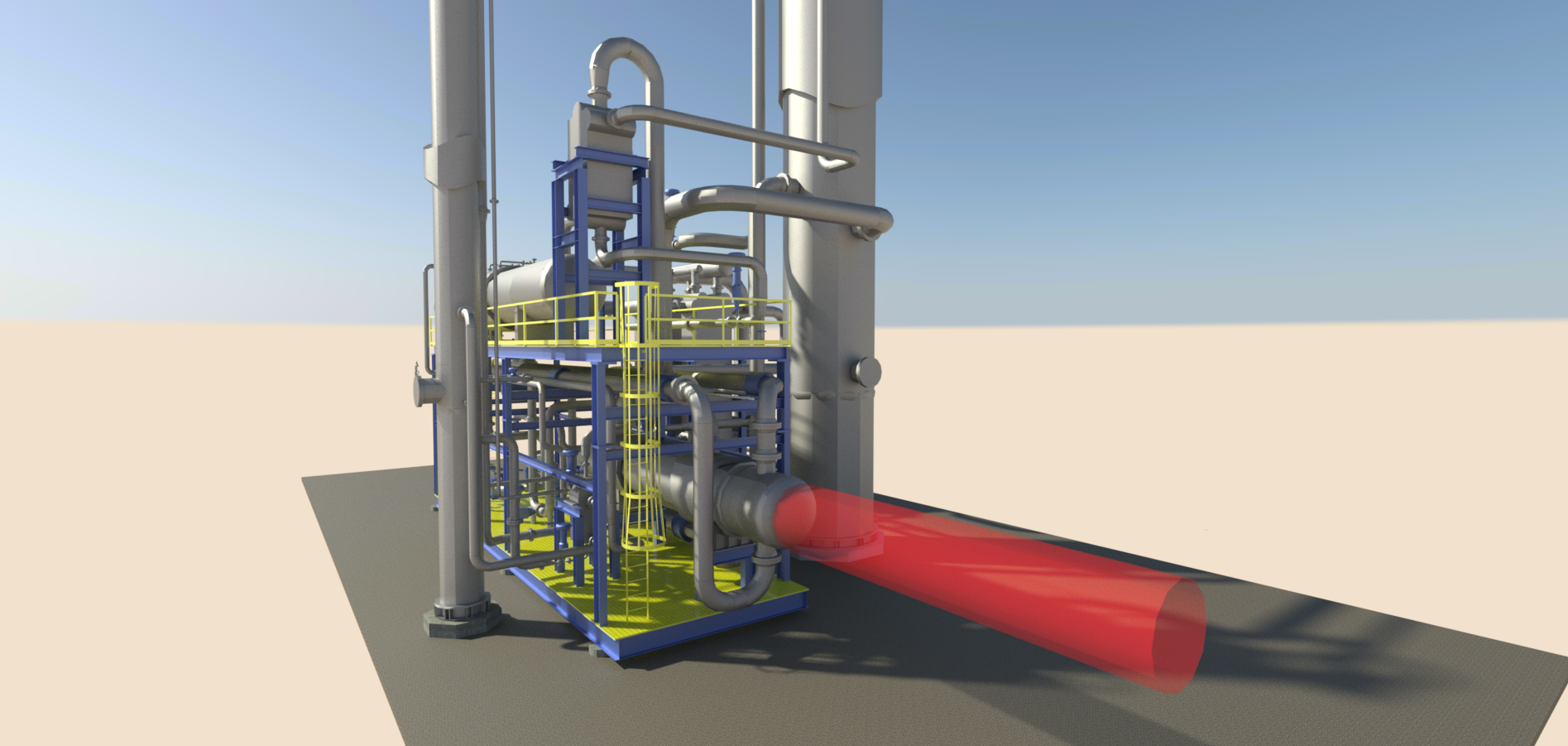

- Modular Skids: Larger NRUs adopt modular skids with insulated equipment and piping. This design improves visibility for troubleshooting and leak detection but requires robust insulation to minimize heat loss and prevent ice formation.

- Key Equipment Considerations:

- Distillation Columns: Use random packing for cost-effective designs or valve trays for flexibility and better turndown (5:1 vs. 3:1).

- BAHE: Insulate and mount on a standalone structure to manage thermal expansion and facilitate maintenance.

- Reflux Pumps: Mechanical seal and sealless cryogenic pumps are available, but account for long lead times in project planning.

Installation Best Practices

- Cleanliness: Blow and scrub piping to remove debris, especially around BAHEs. Use startup screens to capture particulates and consider leaving them as permanent fixtures.

- Avoid Hydrotest: Pneumatically test piping to prevent water freezing issues. Monitor water dew point during dry-out to ensure a bone-dry system prior to startup.

- Lube Oil Prevention: Install efficient filter coalescers upstream to block lube oil entrainment from upstream compressors.

Startup Considerations

- Purge and Leak Testing: Follow a three-step purge process (25%, 50%, 100% of operating pressure) to check for leaks, using the nitrogen vent for blowdowns.

- BAHE Maintenance: Monitor pressure drops (3-5 psi) and have burst plates (25, 50, 75 psi) ready for back puffing to clear debris, if needed.

- Column Inspection: Inspect tower internals for secure hardware and intact distributors, using a crane and air mover for safe access.

Key Takeaways

- Modular skid designs improve troubleshooting but require careful insulation and piping design.

- Cleanliness and pneumatic testing are critical to prevent operational issues like fouling or freezing.

- Thorough startup procedures, including purge and leak tests, ensure a smooth transition to online operation. Single column NRUs suit high-nitrogen, low-capacity operations, while a dual column design excels for efficiency in lower-nitrogen scenarios.

Ready to implement an NRU? Contact us to discuss how to optimize your nitrogen rejection strategy for efficiency and compliance. operations.

Plan an introduction meeting today

Contact our experts today to discover how our innovative solutions can tackle your complex energy challenges