Choosing the Right Nitrogen Rejection Technology

Selecting the right technology for nitrogen removal is a pivotal decision for natural gas operators. With multiple options available, each with unique advantages and challenges, operators must align their choice with operational goals, feed gas composition, and environmental considerations. This blog compares three primary nitrogen rejection technologies and highlights why cryogenic distillation often stands out.

Nitrogen Rejection Technologies

- Membrane Separation:

- How It Works: Uses semi-permeable membranes to separate gases based on molecular size or diffusivity, ideal for bulk nitrogen removal (>15 mol%).

- Pros: Simple operation, minimal equipment complexity.

- Cons: High methane losses in the permeate stream while minimizing compression, or significant compression requirements while minimizing methane losses, and limited ability to polish nitrogen to low levels (<3 mol%).

- Pressure Swing Adsorption (PSA):

- How It Works: Relies on adsorption under controlled pressure to separate nitrogen, using molecular sieves in alternating high/low-pressure cycles.

- Pros: Effective for specific applications, relatively straightforward process.

- Cons: High methane losses, scalability challenges, and substantial compression requirements.

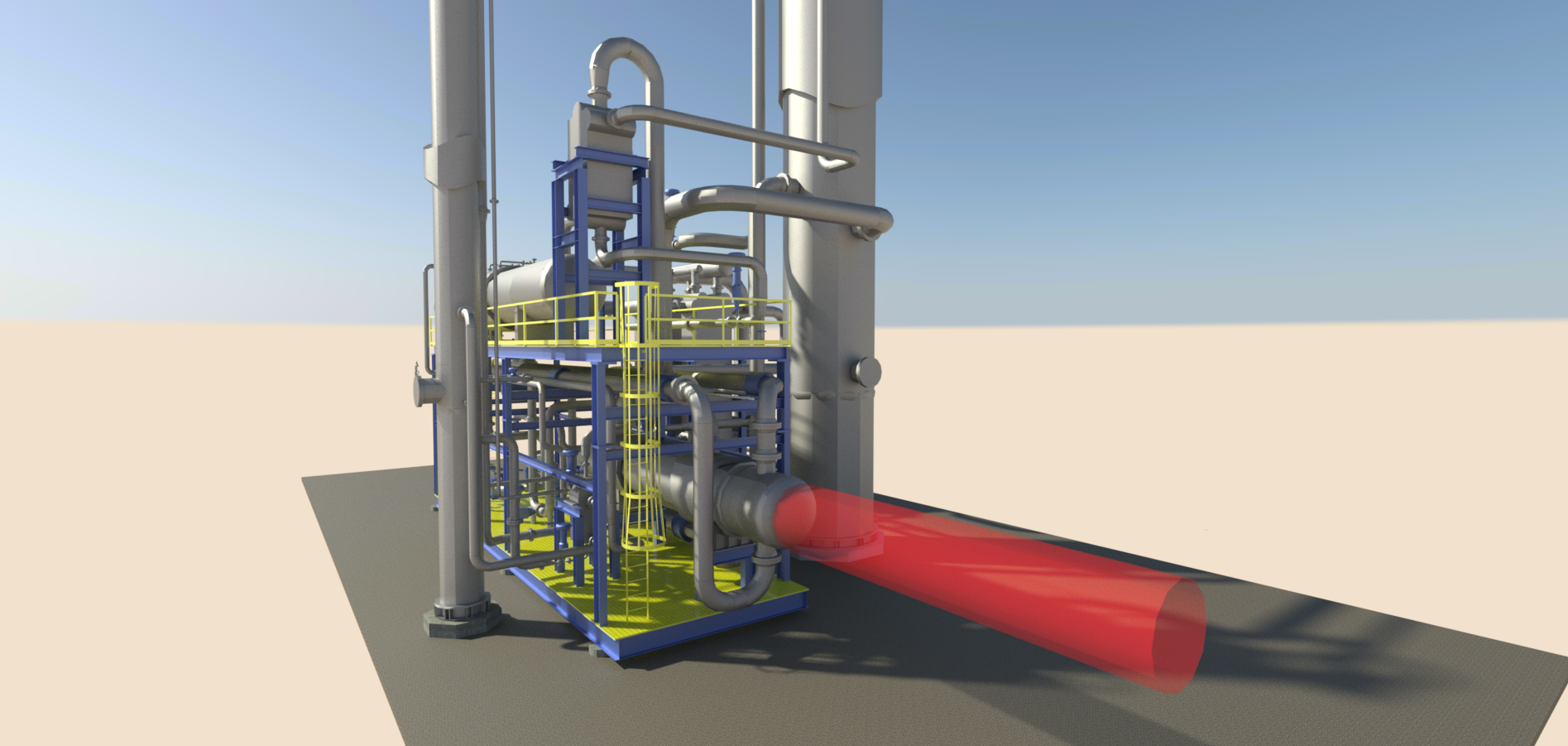

- Cryogenic Distillation (NRU):

- How It Works: Uses low temperatures to separate gases based on boiling points, leveraging the Joule-Thomson (JT) effect for cooling and methane liquefaction.

- Pros: Lower power consumption, reliable operation, minimal methane emissions/losses, and ability to polish nitrogen content in treated gas to low levels (<1 mol% nitrogen).

- Cons: Higher upfront complexity and cost, but offset by long-term efficiency and environmental benefits. Requires a dry feed gas stream with low CO2 content (<50 ppm) to eliminate freezing.

Why Cryogenic Distillation?

Cryogenic NRUs are often the preferred choice for moderate to high nitrogen content due to their efficiency, reliability, and environmental advantages. They require less compression, use conventional gas processing equipment, and can handle varying feed compositions while maintaining product specifications. This makes them ideal for operators prioritizing emissions control and long-term cost savings.

Key Takeaways

- Membrane separation and PSA are suitable for niche applications but struggle with methane losses and scalability.

- Cryogenic distillation offers superior efficiency, reliability, and environmental performance, making it the go-to for most NRU applications for the midstream market.

- Technology selection should align with feed gas nitrogen content, operational goals, and regulatory requirements. Elevated nitrogen levels in shale gas production necessitate NRU deployment.

In our next blog, we’ll explore the design principles behind cryogenic NRUs, including single vs. dual column systems and their impact on performance.

Plan an introduction meeting today

Contact our experts today to discover how our innovative solutions can tackle your complex energy challenges