Optimizing Carbon Capture: A Modular, Cost-Effective Solution for a Leading Energy Producer

Company Overview:

Our client, a leading crude oil and natural gas exploration and production company, manages over 2 billion cubic feet per day of gas and 500,000 barrels of oil equivalent daily. Committed to reducing emissions, they’ve prioritized carbon capture and storage (CCS) initiatives, including a pilot project at a natural gas processing facility to test their proprietary carbon capture solvent.

The Challenge:

The client sought to validate their proprietary solvent in a post-combustion carbon capture process, a critical step toward deploying this technology across their portfolio. Key challenges included:

- Process Design Objective: Develop a carbon capture system for 17.8 MMSCFD of compressor exhaust gas, achieving over 90% capture efficiency.

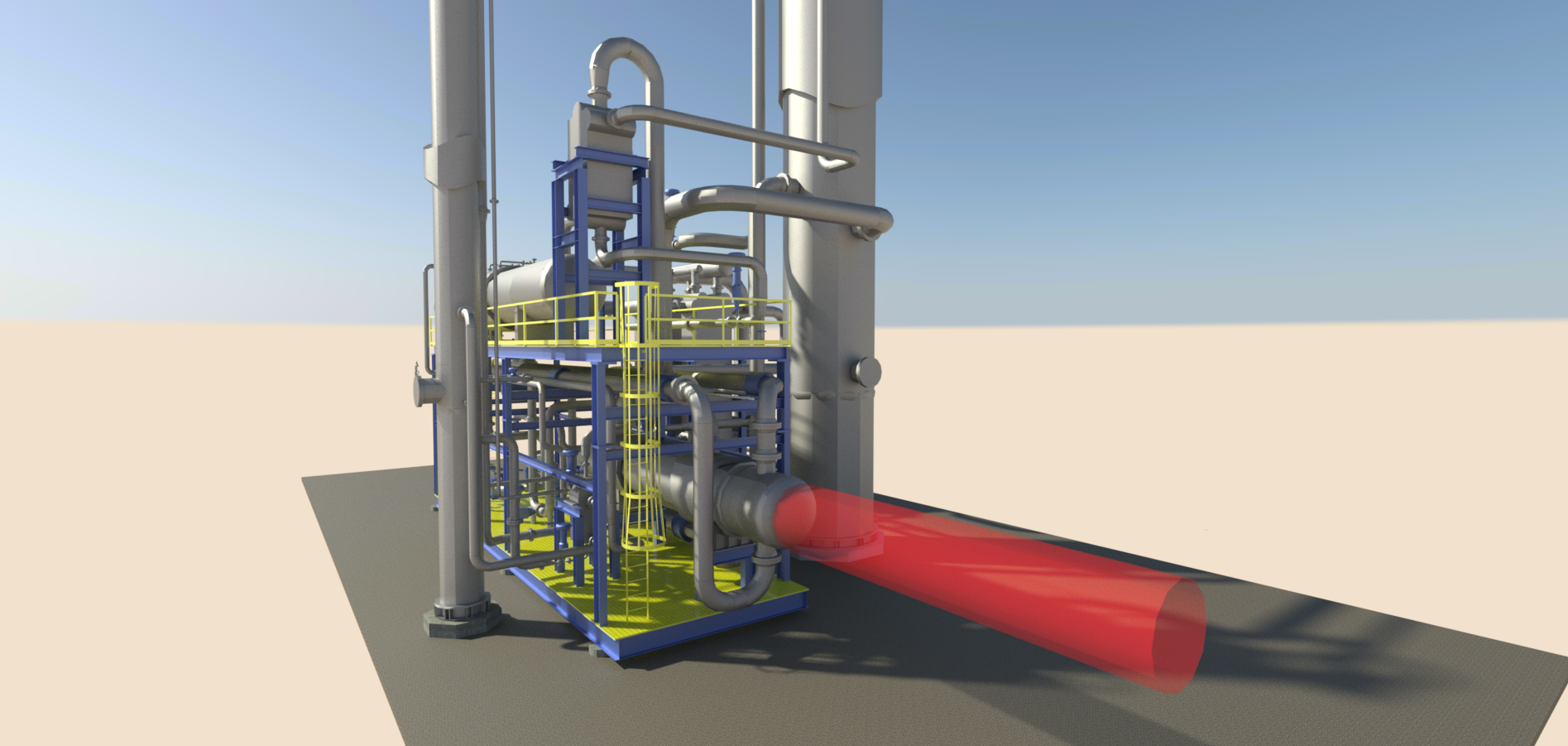

- Highly Modular Design: Create a pre-fabricated equipment package to streamline field installation.

- Low Inlet Pressure: Handle near-atmospheric exhaust gas while minimizing pressure drop to eliminate the need for upstream blowers.

- Minimizing Capital Cost: Design a cost-effective, replicable package to facilitate deployment across multiple facilities.

- Internals Selection: Select tower packing to balance high temperatures, low pressure drop, and performance requirements.

- Heat Integration: Leverage 850°F compressor exhaust gas to heat the amine reboiler via a hot oil system, while evaluating cooling water versus air cooling to optimize plot space.

- Cost/Benefit Analysis: Assess lean/rich exchanger size, reboiler design, bed heights, packing types, and heat integration to maximize value.

The Solution:

Reset Energy delivered a FEED study tailored to the client’s needs, optimizing their proprietary solvent-based carbon capture system for performance and cost efficiency.

Simulation and Process Design

- Proprietary Solvent: Our team collaborated closely with the client to model their a proprietary solvent, iterating on process simulations to optimize performance without full disclosure of the solvent’s composition. Working with internals vendors, we selected packing types to minimize tower bed heights while meeting stringent performance targets.

- The single-column design required approximately 31,200 horsepower (HP).

- The two-column design was significantly more efficient, requiring only about 18,200 HP.

- Heat Integration: We harnessed waste heat from the 850°F compressor exhaust to power the amine reboiler via a hot oil system, eliminating the need for additional heating sources and reducing capital costs.

- The selected, or two-column, design was rated to handle up to 5.0 mol% Nitrogen in the feed gas.

- The two-column design is confirmed to be more effective for Nitrogen concentrations of 25% or less.

Equipment Design and Layout

- Modular Design/Plot Space: Designed for a brownfield site with limited space, our initial cooling water-based exchanger design was re-evaluated. Switching to air-coolers reduced costs and met plot space constraints without compromising performance.

- Packing Types/Material Selection: We evaluated packing options to address high temperatures and cost constraints, reducing tower diameters and bed heights. In lower-temperature sections like the amine contactor and water wash, we opted for cost-effective plastic packing over stainless steel, ensuring compatibility and durability.

The Results:

- Achieved over 90% carbon capture efficiency.

- Delivered a cost-benefit analysis that optimized equipment selections for maximum value.

- Implemented design changes that kept the project within budget while meeting all performance objectives.

This case study highlights Reset Energy’s successful design and implementation of a modular carbon capture system that achieved over 90% capture efficiency using a proprietary solvent, while integrating waste heat and optimizing equipment to reduce capital costs. Through detailed simulation, material selection, and cost-benefit analysis, the project met performance goals and budget constraints, enabling scalable deployment across the client’s facilities.

Plan an introduction meeting today

Contact our experts today to discover how our innovative solutions can tackle your complex energy challenges