Condensate Stabilizers Can Help Increase Revenue with Recovered Natural Gas

For process and natural gas engineers, maximizing operational efficiency and profitability are always top priorities. One such opportunity lies in a widely used yet often underestimated piece of equipment—the condensate stabilizer. These systems transform potential waste into valuable resources.

This blog explores how condensate stabilizers optimize production, recover valuable natural gas liquids (NGLs), and add measurable value to your operations.

What Are Condensate Stabilizers?

Condensate stabilizers are processing units that treat hydrocarbon condensate by removing lighter hydrocarbons to reduce the volatility, or Reid Vapor Pressure (RVP). The process ensures the safe transport and storage of stabilized condensate while recovering valuable natural gas liquids (NGLs), boosting efficiency and profitability.

Key Benefits of Condensate Stabilizers in Natural Gas Processing

Condensate stabilizers offer significant advantages for midstream operations.

Simulation and Process Design

- Recover Valuable NGLs: Extract propane, ethane, and butane from natural gas condensate, transforming waste into profitable products and maximizing resource utilization.

- Ensure Product Safety: Reduce Reid Vapor Pressure (RVP) and improve density to meet transport and market standards. Lower RVP decreases the presence of volatile compounds, significantly reducing the risk of vapor pressure buildup in storage tanks and pipelines. This minimizes the potential for vapor releases that could lead to explosions or fires, enhancing safety during handling, transport, and storage.

- Maximize Return on Investment: Operating condensate stabilizers involves higher upfront investment and ongoing costs, such as energy and maintenance. However, revenue generated from recovered natural gas liquids (NGLs) can offset these expenses and improve the bottom line.

How Do Condensate Stabilizers Work?

Condensate stabilization relies on advanced thermal separation techniques. Here’s how the process works:

- Feed Entry to the Stabilizer Column: Raw hydrocarbon condensate enters the stabilizer column, designed with trays or packing which allows lighter molecules to travel upward and heavier molecules to move downward, driven by heat and gravity.

- Heating and Cooling for Optimal Separation: The reboiler at the column’s base adds heat, creating vapor that rises and carries lighter hydrocarbons upward. A condenser at the top of the column removes heat, condensing the vapor into liquid that flows downward, enriched with heavier hydrocarbons. The reboiler and condenser work in tandem to separate natural gas liquids (NGLs) from stabilized condensate and meet product specifications.

- Customized Product Outputs: Stabilizers can be fine-tuned to produce condensate with a specific Reid Vapor Pressure (RVP), meeting safety and market standards while maximizing NGL recovery. Stabilizers can be fine-tuned to produce condensate with a specific Reid Vapor Pressure (RVP), meeting safety and market standards while maximizing NGL recovery. This optimization ensures that your operation maximizes every barrel of processed hydrocarbons.

Why Condensate Stabilizers Matter for the Future of Natural Gas:

The growing focus on efficiency and environmental responsibility is reshaping the natural gas industry. Condensate stabilizers represent a solution that aligns these evolving priorities. By recovering valuable NGLs, optimizing operations, and reducing waste, these systems deliver multifaceted benefits that position businesses to thrive in a competitive landscape.

Unlock Greater Potential

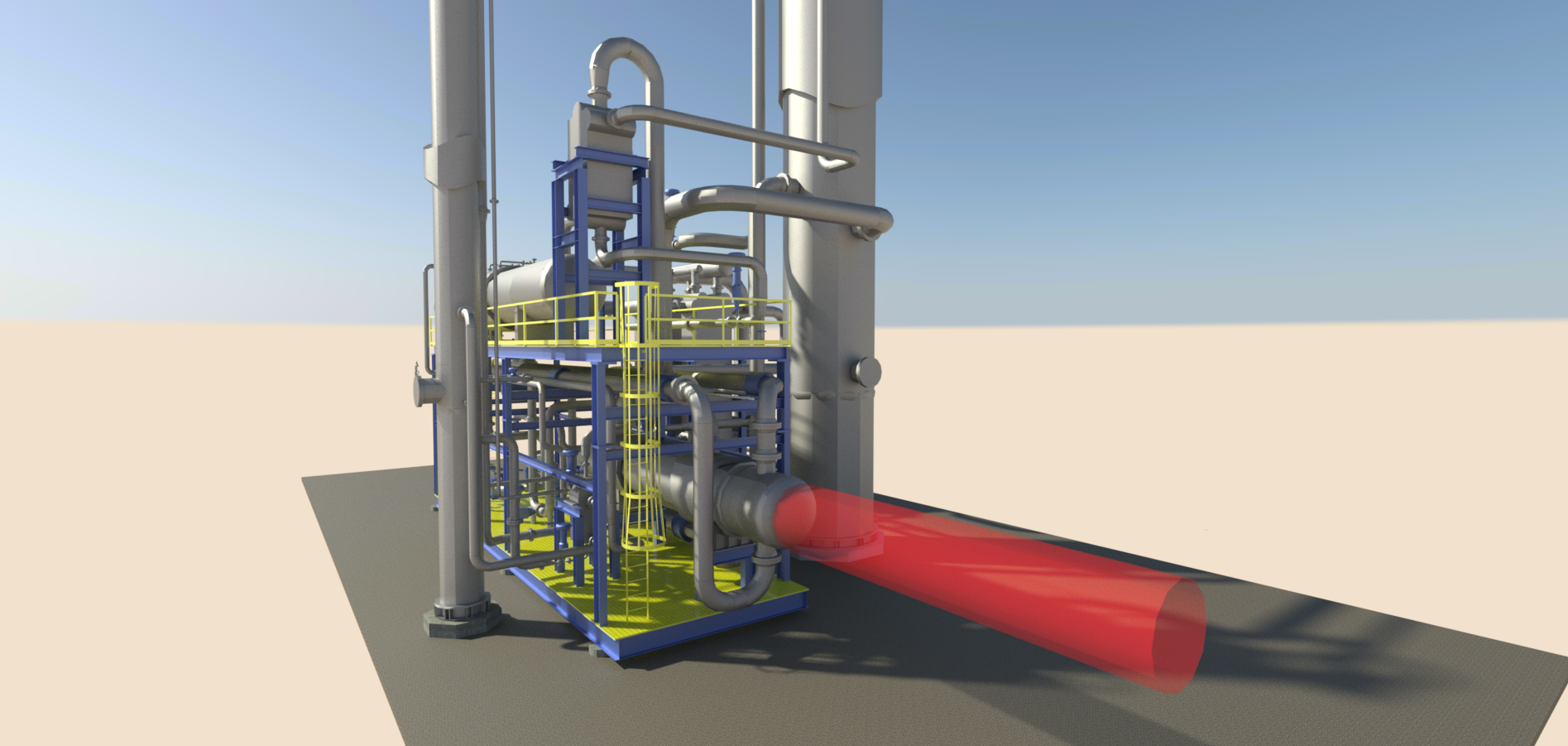

Reset Energy designs every stabilizer to specific customer compositions and product specifications. Further, during the initial process design, Reset optimizes the split of NGL and Stabilized Condensate products to maximize value for our client’s economics.

Contact Reset Energy today to learn how condensate stabilizers can help turn your natural gas operations into a competitive advantage and how our solutions can assist in seamlessly integrating condensate stabilization into your operations.

Plan an introduction meeting today

Contact our experts today to discover how our innovative solutions can tackle your complex energy challenges