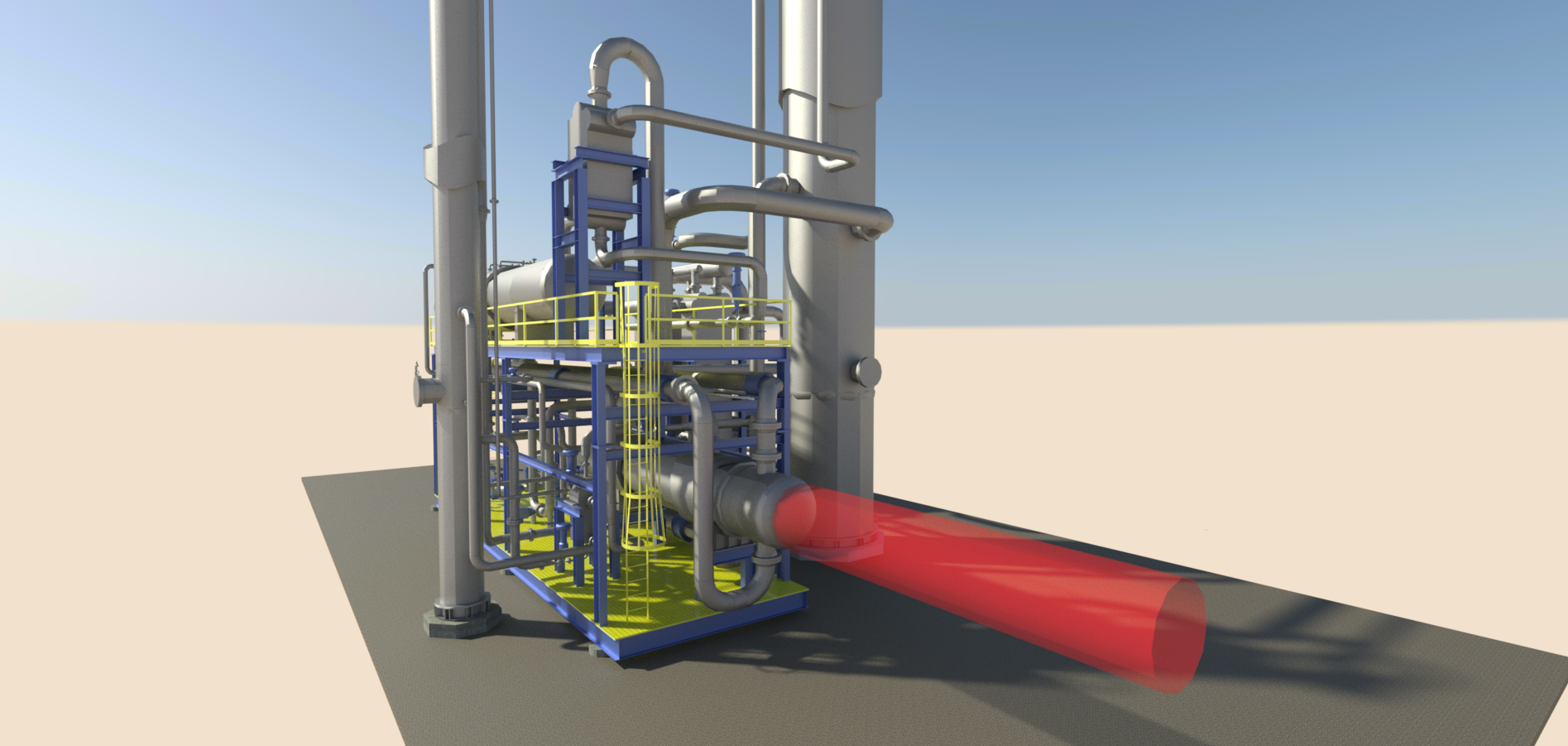

Our advanced amine treating solutions are specially engineered to remove impurities such as hydrogen sulfide (H2S) and carbon dioxide (CO2) from natural gas, flue gas, tail gas or acid gas, and syngas. Our solutions are designed to utilize both generic and proprietary amine solutions. With a focus on flexibility, efficiency, and durability, our solutions are tailored to meet the dynamic needs of the industry.

Amine Treating Features

Specifications to Suit Your Needs

Our Amine Treating Systems come in a range of sizes and capacities to meet diverse operational needs:

- 20 GPM – 4000 GPM to cater to various scales of operation.

Key Features that Set Us Apart

Get Started with Our Amine Treating Systems!

Experience the difference that innovative, sustainable, and high-efficiency solutions can make. Let’s work together to enhance your gas treating process and achieve your operational goals.

Our Projects

10000 BPD Stabilizer Package

4000 BPD NGL Amine Treater

1600 GPM Amine Treater, 3 MMBtu_Hr. TEG Dehydrator, 10,000 BBL_D Condensate Stabilizer

Experience industry-leading reliability and performance as we redefine gas treatment standards. Explore our transformative solutions today. Innovative gas processing & treatment solutions that solve complex energy challenges